Privacy Policy Update

Click here to learn about the new Privacy Policy updates from Practical Components.TMV PoP - Through Mold Via Package Dummy Component

TMV® PoP Dummy

Through Mold Via Package - Discontinued

DISCONTINUED. After three years of development, Amkor has introduced the next generation PoP solution. This new technology is called Through Mold Via (TMV®). The new TMV® technology is used to create interconnect vias through the mold cap, it also provides a more stable bottom package that enables the use of thinner substrates with a larger die to package ratio. TMV® enabled POP can support single, stacked die for wirebond and FC designs.DISCONTINUED.

TMV® technology enables next generation PoPs by:

* Removing bottlenecks for fine pitch memory interfaces

* Enhancing warpage control and bottom package thickness reduction

* Increasing die to package size ratios

* Supporting wirebond, flip chip, stacked die and passive integration

* Improving board level solder joint life

White paper articles and technical presentations are available on Practical Components web site at www.practicalcomponents.com or Amkor Technology's web site at www.amkor.com.

|

TMV® PoP-Mating Top and Bottom Daisy Chain Samples |

||||||

|

Part Description |

I/O Count |

Pitch |

Body Size |

Ball |

Ball |

Quantity |

|

14mm Body Size |

||||||

|

A-PoP200-.5mm-14mm-DC |

200 (top package) |

.5mm |

14mm |

27x27 |

Perimeter |

119 |

|

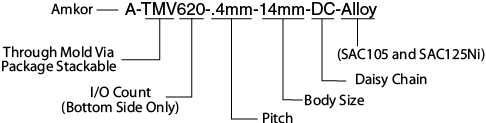

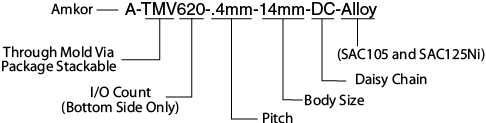

A-TMV620-.4mm-14mm-DC |

620 (bottom package) |

.4mm |

14mm |

33x33 |

Perimeter |

119 |

Notes

* Fine pitch 0.4mm bottom package footprints.

* Stacked package heights of 1.2mm nominal (see Stack Up table on

following pages).

* Dummy Package configurations compliant with JEDEC standards.

* Moisture Resistance Testing is JEDEC Level 3 @ 260 °C.

* Temp Cycle -55/+125 °C, 1000 cycles.

* HAST 130 °C, 85% RH, 96 hours.

* Temp/Humidity 85 °C/85%RH/1000 hours.

* High Temp Storage 150 °C, 1000 hours.

* Board level Thermal Cycle -40/+125 °C, 1000 cycles.

* Parts packaged in JEDEC matrix trays.

* PoPs are only available Pb-free (not Tin-Lead). Available alloys are: (SAC105) 98.5%Sn/1.0%Ag/0.5%Cu Top Package and (SAC125Ni) 98.2%Sn/1.2%Ag/0.5%Cu/0.5%Ni bottom package.

* It is recommended that parts be pre-baked at 125 °C for 48 hrs before using parts regarding moisture concern.

* PoP's are not available without solder balls.

Practical Components is the exclusive distributor of

Amkor Technology Mechanical Components.

Part Description System

|

Ball Diameter |

|

|

I/O Count |

Ball Diameter |

|

200 |

0.33mm |

|

620 |

0.30mm |

Notes

* Amkor supporting data is available on our website for: Board Level Reliability (BLR), PoP application notes, PoP Stencil & Stacking paper for SMT Conditions.