Privacy Policy Update

Click here to learn about the new Privacy Policy updates from Practical Components.Flip Chips

Flip Chips

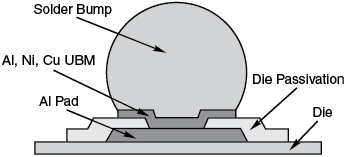

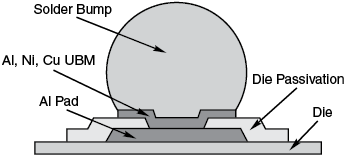

Flip Chip describes the method of electrically connecting the die to the package carrier. The package carrier, either substrate or leadframe, then provides the connection from the die to the exterior of the package. The interconnection between die and carrier in flip chip packaging is made through a conductive bump that is placed directly on the die surface. The bumped die is then flipped over and placed face down, with the bumps connecting to the carrier. After the die is soldered, underfill is applied between the die and the substrate, around the solder bumps. The underfill is designed to contract the stress in the solder joints caused by the difference in thermal expansion between the silicon die and carrier.

UBM is the Al/NiV/Cu (under bump metallization) covering about 1% of the wafer which is under the bumps only. Nitride passivation is an invisible glass-like protective coating over 99% of the wafer, except under the bumps. The bumps will not stick to the Nitride, only the UBM. Nitride coating is standard for all Flip Chip wafers.

|

Flip Chips |

||

|

Part Numbers: |

FA10-200x200 |

PB08-200x200 |

|

Die Size |

200 x 200 mils |

200 x 200 mils |

|

Bump Pitch |

254 µm, 10 mil |

203 µm, 8 mil |

|

Passivation Via |

80 µm |

73 µm |

|

UBM Diameter |

102 µm |

95 µm |

|

Bump Height |

120 µm |

98 µm |

|

Bump Diameter |

135 µm |

120 µm |

|

No. of Bumps |

317 |

88 |

|

Final Metal Pad Size |

127 x 127 µm |

115 x 115 µm |

|

Metal Composition |

98/1/1 Al/Cu/Si |

98/1/1 Al/Cu/Si |

|

Packaging |

||

|

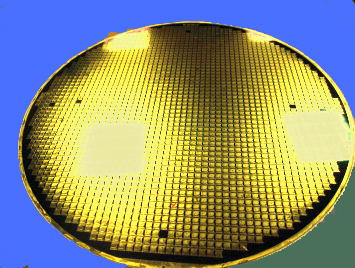

Uncut Wafer* |

5" Wafer |

5" Wafer 400x400mil (86 Die) |

|

Tray |

Sawed 5" Wafer |

Sawed 5" Wafer |

|

Tape and Reel |

Call For |

Call For |

Notes

* * Die count represents expected yield per wafer.

* All die is packaged in waffle pack trays unless otherwise specified.

* All test wafers are currently 5" diameter and are 0.635mm thick. Passivation is one-micron thick plasma Nitride with round via openings.

* The potential multiple is the number of die repeats on the wafer. With the wafer orientated flat down, a right hand coordinate system applies.

* Die size is from scribe line to center-to-center. Scribe width is 0.05mm passivated. Each bump is electrically connected to one other bump and isolated from all others to facilitate electrical test.

* Bump pitch is defined as center-to-center distance between passivation openings.

* Bump height is defined as silicon surface to the top of the bump.

* Bump diameter is defined as the maximum diameter.

* UBM = Under Bump Metallurgy

* Lead-free parts are available with 95.5% Sn/ 3.5% Ag/ 1.0% Cu alloy.

* Unbumped wafers are available upon special request.

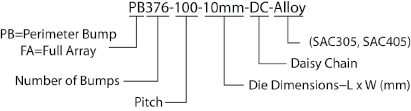

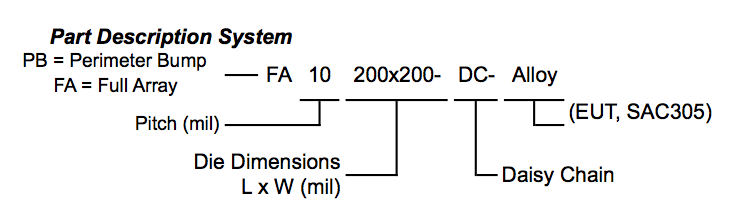

Part Number System

* Add "WR" to end of part number for Wafer Cut and left in Seal Ring.

* Add "TR" to end of part number for die on Tape and Reel.

* Add "EUT" to end of part number for Eutectic.

* Add "LF2" to end of part number for Lead-Free.

* Add "W" to end of part number for Uncut Wafer.

* Add "unbumped" to end of part number for unbumped wafer/die.

FCT Bump Structure

Request Catalog

Request or download our catalog and sign-up for our newsletter.

Continue